Tailor made Jigs and Accessories for High-Precision Mechanised Parts

Efficient manufacturing procedures and high-quality production depend heavily for the precision and reliability of the equipment utilized to create, assemble, and evaluate parts. For lace front wigs that job with high-precision physical parts, custom jigs and fixtures play a critical role in ensuring reliability and streamlining businesses. This blog is exploring various aspects of custom jigs and fixtures manufacturing, their very own applications, as well as the rewards they offer in achieving high-precision standards.

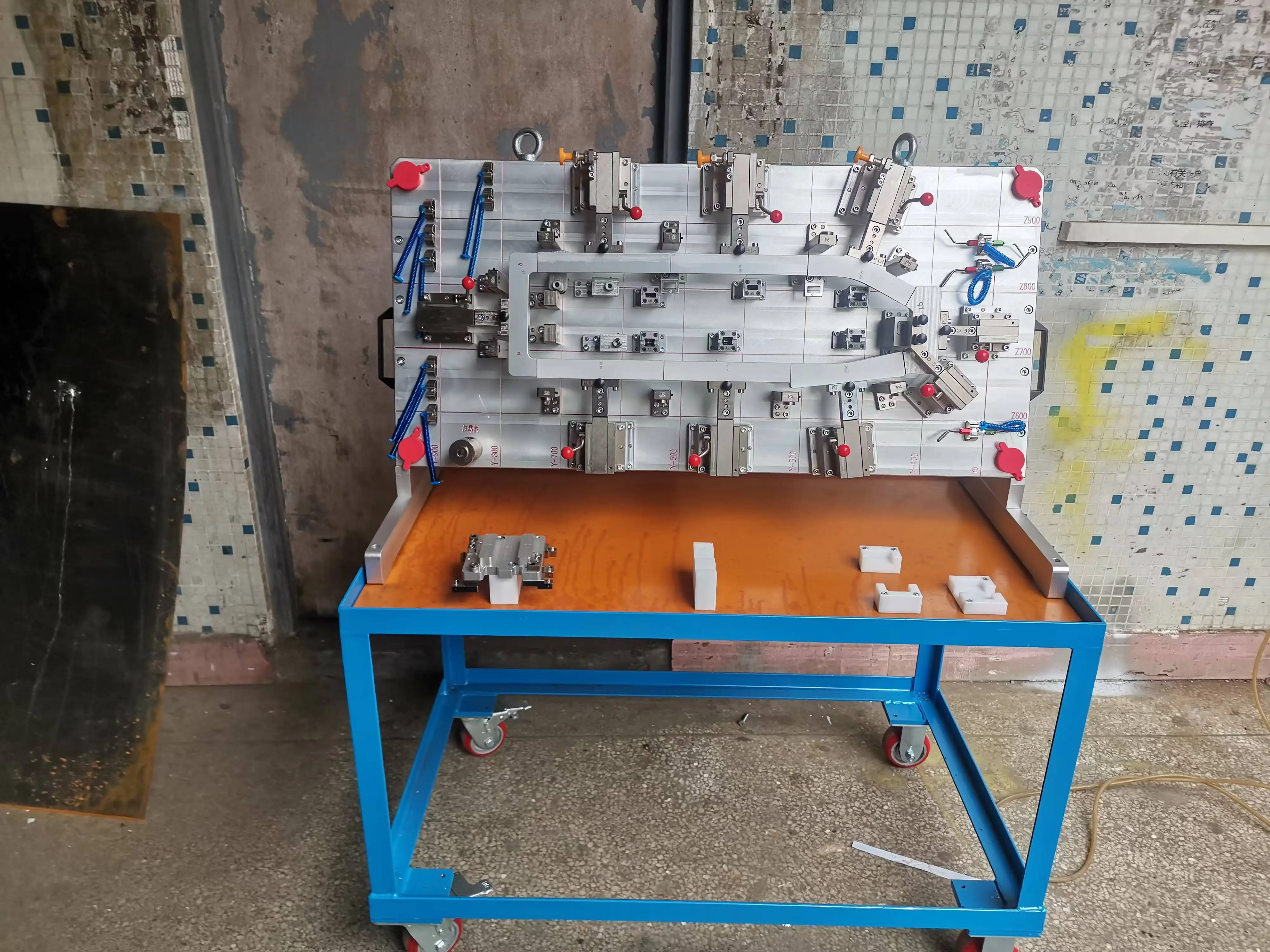

Designing Fixtures to Meet Tolerances of CNC and Laser-Machined Elements

When working with advanced manufacturing solutions like CNC machining and laser cutting, achieving tight tolerances is non-negotiable. Custom made fixtures are especially designed to keep components securely on place, ensuring steady alignment and reducing the risk associated with errors during engineering processes. Whether typically the goal is always to create intricate geometries for aerospace components or produce finely comprehensive parts for electronic devices, custom fixtures give unparalleled stability and precision. Companies specialized in in jigs in addition to fixtures manufacturing make use of innovative designs tailored to the unique specifications of each and every application, optimizing accuracy and productivity.

How Custom Jigs Improve Quality Inspection in Mass Generation

Mass production needs speed and regularity, but quality cannot be compromised. Custom jigs designed for evaluation purposes streamline the process of considering mechanical parts. These people allow inspectors to quickly assess whether components meet design specifications without wasting excessive time about setup and dimension. These jigs usually are particularly useful throughout industries like auto and electronics, exactly where large volumes involving parts need in order to be checked with regard to defects. The mix of efficient design in addition to precision engineering makes sure that quality control processes are faster, more reliable, and less labor-intensive.

Case Study: Precision Fixtures for Complex Motor Component Assembly

One particular of the perfect examples of the value of custom features is their software in assembling sophisticated engine components. Accuracy fixtures are designed to hold elements in exact jobs during assembly, insuring that every aspect fits together properly. Without these fittings, inconsistencies in positioning could lead to performance concerns or maybe catastrophic problems. For instance, in auto and aerospace companies, custom fixtures utilized in the assembly involving gearboxes or generator engines make sure that even the most elaborate parts meet exacting safety and features standards. Such situations demonstrate the critical role custom lures and fixtures developing plays in sustaining industry excellence.

Materials Commonly Used in High-Accuracy Jigs and Their Benefits

The selection of elements in jigs plus fixtures manufacturing is definitely just as important as the style alone. Depending on lace front wigs human hair , materials like steel, aluminium, and high-performance plastic materials are generally employed. Metallic, known for its strength and resistance in order to wear, is perfect for applications involving heavy tons or repetitive work with. Aluminum, being lightweight and corrosion-resistant, is definitely often chosen intended for portable fixtures or even when minimizing weight is crucial. High-performing plastics bring the advantage of low friction and light properties, making these people suitable for specialized uses in sensitive operations. Each stuff offers unique benefits, enabling manufacturers in order to customize jigs plus fixtures to meet up with specific operational demands.

To summarize, the choice of materials with regard to jigs and fittings plays a pivotal role in figuring out their performance and sturdiness. By understanding the particular specific requirements of the application, producers can choose materials that provide the particular optimal balance associated with strength, precision, and even cost-efficiency. Whether it's the robust strength of steel, typically the lightweight versatility involving aluminum, or perhaps the particular attributes of top-end plastics, the appropriate choice ensures increased productivity and reliability in manufacturing operations.