Materials and Technologies Shaping the Future of Fixtures and Jigs

The making globe is in consistent flux, progressing with new products and advanced technologies that drive performance, accuracy, and sustainability. For specialists in the production industry, especially those associated with components and jigs making, staying on top of these developments is crucial. This blog checks out exactly how arising products and modern technologies are transforming the production and application of jigs and components. From sophisticated products supplying improved performance to the assimilation of clever innovations, we'll discuss the innovations shaping this market and pathways to accomplishing sustainability.

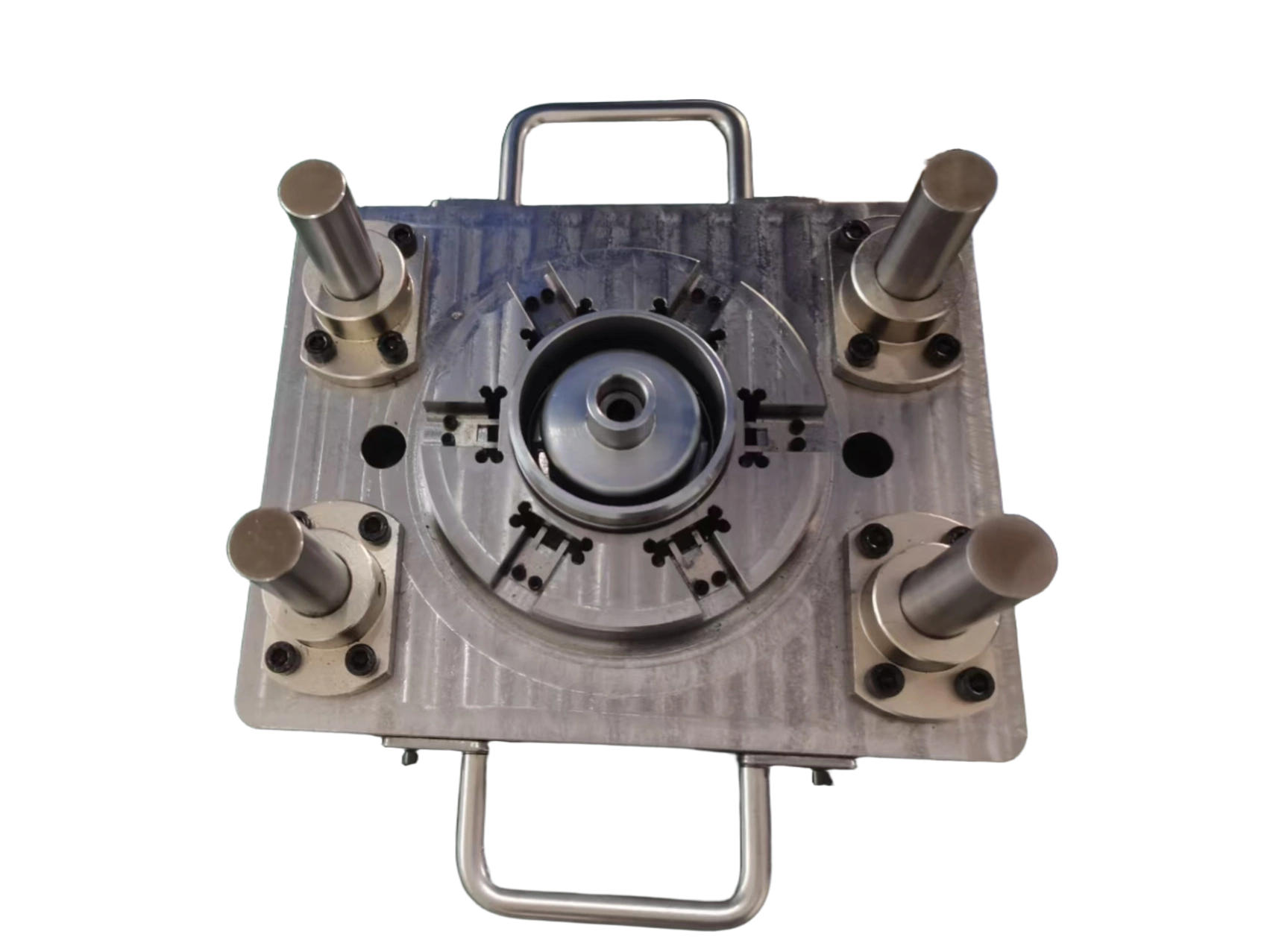

Discovering Advanced Products in Fixtures Production

The introduction of sophisticated materials has actually revolutionized the fixtures manufacturing landscape, using both durability and customization options. Commonly, human hair wigs like steel and aluminum were the essentials of components due to their stamina and resilience. Now, high-performance plastics and composite materials are acquiring grip, thanks to their lightweight residential or commercial properties and cost-effectiveness. For precision mechanical components, products like carbon fiber compounds have actually come to be indispensable, offering unequaled tensile toughness and reducing deterioration. Additionally, these products offer much better resistance to environmental stress factors like rust or extreme temperatures, making them optimal services for sectors ranging from automotive to aerospace. Organizations specializing in jigs and components producing currently have a lot more choices than ever before, enabling them to tailor materials to the demands of particular tasks and industries.

The Effect of CNC Machining on Jigs Production

The advent of CNC (Computer Numerical Control) machining has actually significantly enhanced the accuracy and performance of jigs making. Unlike standard methods that needed manual treatment, CNC machining allows for automated, repeatable processes to create components with remarkable precision. This is specifically crucial in fields where jigs play a critical function in guaranteeing manufacturing uniformity, such as in electronics or heavy machinery. CNC equipments additionally master functioning with a range of materials, from metals to customized plastics, enabling substantial customization. Firms can swiftly adapt their manufacturing lines to fulfill certain client or product needs, therefore minimizing lead times and improving overall performance. With CNC machining, the production of jigs has actually moved from being a labor-intensive process to a high-tech, streamlined procedure that enhances scalability for businesses.

Incorporating IoT in Fixtures and Jigs for Smart Manufacturing

The Internet of Things (IoT) is redefining wise manufacturing, including making use of components and jigs. IoT assimilation permits real-time data collection and monitoring, making it possible for producers to track performance metrics and maximize processes. For instance, sensing units installed in fixtures can keep an eye on stress, positioning, or positioning, providing responses to operators or directly changing setups to maintain precision. This level of smart automation makes certain constant high quality while decreasing human mistake. In addition, IoT-enabled jigs and components can be linked to broader manufacturing networks, integrating flawlessly with other advanced devices like robot welding stations or automated assembly line. These abilities are vital for organizations aiming to keep an affordable advantage in sectors like vehicle or aerospace, where accuracy and dependability are paramount.

Lasting Practices in Precision Mechanical Parts Manufacture

Sustainability is becoming increasingly vital across all markets, consisting of jigs and fixtures manufacturing. By embracing environment-friendly products like recycled metals and bioplastics, producers are decreasing their ecological impact while keeping premium production. In addition, energy-efficient production methods, such as CNC machining with enhanced tool courses, add to decrease electrical energy usage and very little waste. curly lace front wigs from developments like additive manufacturing or 3D printing, which makes use of much less material and generates practically no waste. These sustainable practices not just profit the world however additionally boost expense performance as organizations reduce materials waste and energy expenses. For industries making every effort to align their procedures with global sustainability objectives, embracing lasting practices in precision mechanical components construction is no much longer optional but necessary.

The assimilation of innovative products, CNC machining, IoT technologies, and sustainable techniques is reshaping the landscape of components and jigs producing. Business that adapt to these advancements can better fulfill evolving industry needs, enhance operational performance, and maintain an affordable edge. At the same time, these advancements encourage services to add to more comprehensive sustainability goals, making sure a positive effect on both the industry and the atmosphere. For companies aiming to raise their production capabilities, staying informed about brand-new products and modern technologies is critical. If you prepare to carry out these technologies in your operations, discover the advanced services. Discover how our proficiency in jigs and components producing can drive your success.